Application options

Individuelle Lackierung und umfassende Oberflächengestaltung: Handwerk oder Robotertechnik

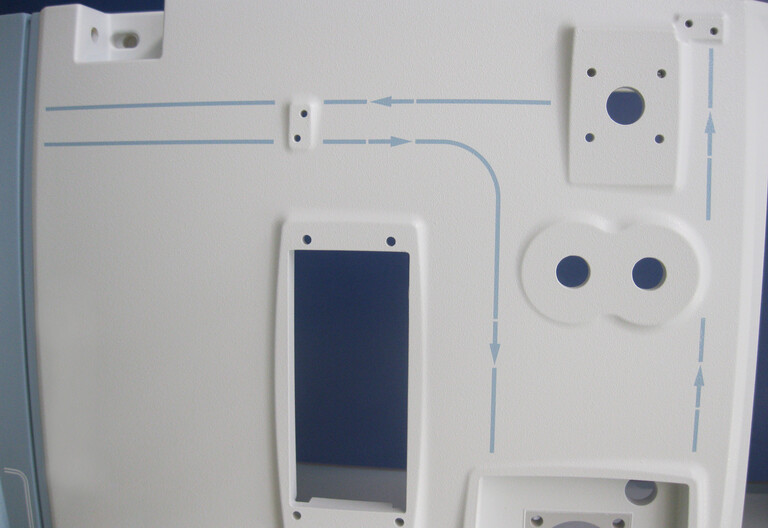

Plastic molded parts

Application options

The choice between robotic or manual painting depends on a company's priorities: either mass production with high efficiency and consistency or flexibility, adaptability and high quality craftsmanship.

Automatic painting

- Efficiency and speed:

Robotic painting is particularly efficient for large quantities as robots can paint continuously and evenly, without fatigue or variations in quality.

- Consistency and precision:

Painting results are very consistent and precise as robots are precisely programmed to adhere to specific movement patterns and painting parameters.

Hand painting

- Flexibility:

Hand painting is particularly suitable for smaller quantities or products that require individual attention, such as prototypes, customised products or products with complex shapes.

- Quality and customisation:

Hand painting allows for fine-tuned customisation of the paint finish to meet specific requirements and offers high quality due to the skilled handling of the painters.

- Versatility:

Painters can respond quickly to changes and apply different painting methods depending on the surface or design requirements.

To complete the surface and finalise the object, we take over the further surface design, such as the application of company logos and lettering.

Printing

Surface design with

- Screen printing

- Transfer printing

Gluing

Surface design e.g. of

- Company logos

- Labelling