RIM materials

Polyurethane, the material for all applications

Plastic molded parts

RIM materials

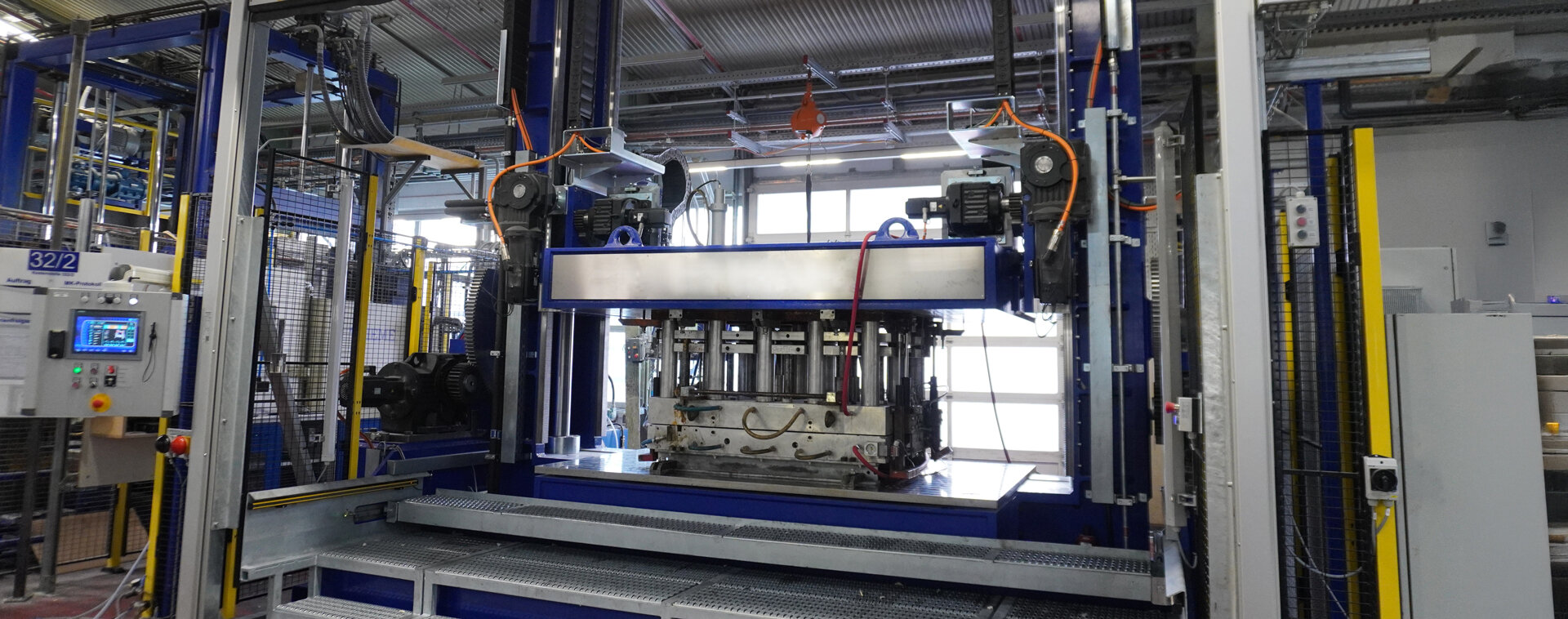

Reaction Injection MoldingPolyurethane, the material for all applications. Hardly any other material combines aesthetics, ergonomics and function in this ideal form.

Thieme uses PUR material systems from the leading raw material manufacturers Covestro and BASF.

The materials are purchased as pre-formulated systems and processed into high-quality molded parts.

The material offers

- economic efficiency

- Freedom of design

- High dimensional stability

- High rigidity

- Low weight

- Impact resistance

- Sound absorption

- Good thermal properties

- Chemical resistance

- Flame retardant according to UL Subject 94

- Recyclability

Advantages of PUR

- Use of cost-effective aluminium tools

- Great freedom of construction and design

- Minimisation of assembly costs through function integration

- Reduction of logistics costs

- Reproducibility

- High reproduction accuracy

- Creation of filigree areas

- Complex three-dimensional geometries

- Fulfilment of chemical and physical requirements

- Integration of assembly parts

- Extensive painting options and pleasant haptics

- EMC shielding possible

The right material for each product

PUR integral hard foarm (IHS)

- Sandwich-style design with high inherent rigidity

- Extraordinary design flexibility

- Good thermal and acoustic insulation properties

More about PUR integral hard foarm

PUR compact foam (K110)

- Compact structure and high impact strength

- Alternative to injection moulding

- Components up to 6 m² projected area

More about PUR compact foam

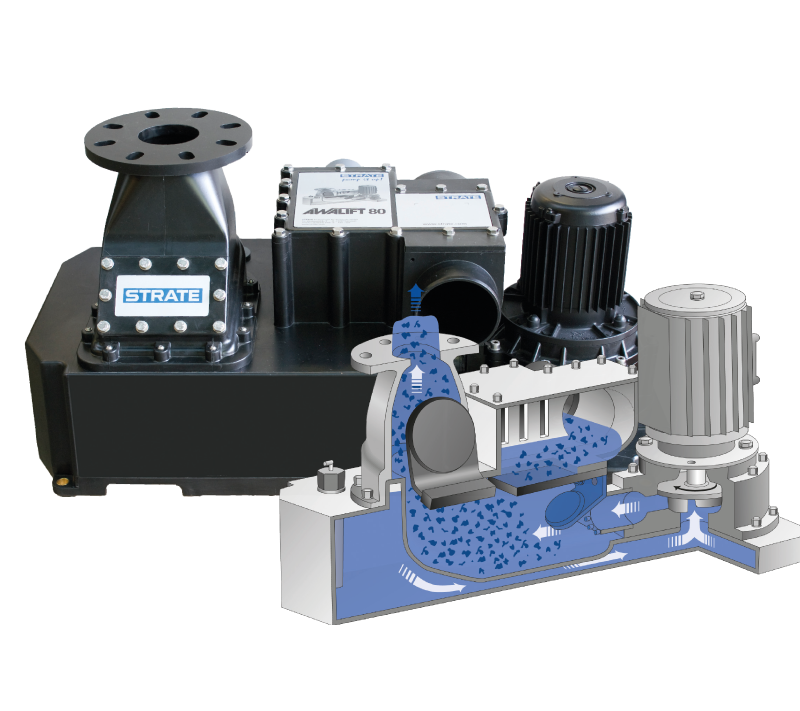

PUR casting system (GS)

- The material for mechanically and chemically stressed functional parts

- Alternative to grey cast iron or steel

PUR flex foam (Flex)

- High impact strength also at low temperatures

- Extraordinarily durable

- Aesthetics possible by means of structured tool surfaces

More about PUR flex foam

PUR energy absorption foam (EA)

- Kinetic energy is converted into deformation energy

- Can be optimally used for the most diverse requirements

- Passive passenger protection for all vehicle areas

PUR semi-hard integral foam (IS)

- For low-weight comfort components

- The compression hardness can be changed by means of variable densities

- Polyurethane system for acoustic solutions

- PUR acoustic foam in various designs

- Ideal for airborne sound insulation (sound absorption), airborne sound insulation and structure-borne sound insulation

THIEME 60 FRR - EN 45545 (R1/HL2)

- Sandwich-style construction with high inherent rigidity

- Extraordinary design flexibility

- Good thermal and acoustic insulation properties

- EN 45545

THIEME 110 FRR - EN 45545 (R1/HL2)

- Compact structure and high impact strength

- Alternative to injection molding

- Components up to 6 m² projected area

- EN 45545