Quality laboratory

State-of-the-art measurement technology monitors the quality of plastic moulded parts

Plastic molded parts

Quality laboratory

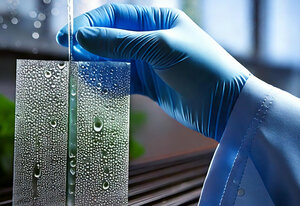

Thieme's quality laboratory monitors the quality of plastic moulded parts using state-of-the-art measuring technology. Reliable test methods ensure the highest product standards.

Overview of the equipment and activities of the quality laboratory:

Incoming goods inspections

- Density determination of the raw components

- Reactivity, foaming times and density determination in the cup test

- Viscosity determination

Tests during production

- Determination of the air load

- Determination of the flame retardant content

- Determination of the proportion of non-combustible fillers

Optical tests

- Microscopy

Mechanical tests

- Density determination

- Surface hardness according to Shore D

- Tensile test

- Bending test

- Compression test

- Impact strength

- Bush pull-out strength

Thermal tests

- Fire behaviour according to DIN 75 200 and FMVSS 302

Lacquering

- Determination of coating structure and paint thickness

- Determination of paint adhesion

Resistance tests

- Heat storage

- Condensation climate test